Home » One year of the UK Agri-Tech Centre

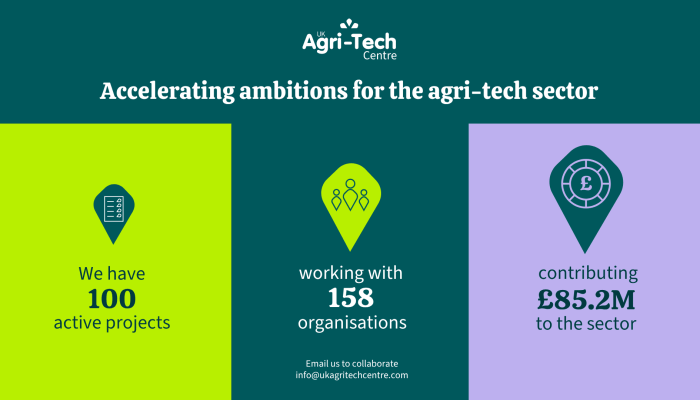

Over the past year as the UK Agri-Tech Centre, we have accelerated ambitions across the agriculture sector.

Through our commitment to driving innovation and fostering cross-sector collaboration, we have supported transformative advancements that address pressing industry challenges and unlock new opportunities.

It has been an incredible year of innovation, collaboration and growth and we are delighted to recognise some of the companies we have worked with that have grown, expanded their product ranges and attracted investments, showcasing their contributions to the sector.

Read on to discover the successes of the businesses we are working with.

For Thomas Farrugia of Beta Bugs, the advantages of growing his business with the UK Agri-Tech Centre have included access to facilities, project support and wider exposure to our UK and international network.

“Growing our business would have been a challenge if this space did not exist,” says Thomas, who established Beta Bugs in 2017 with a mission to provide high-quality genetics to black soldier fly producers.

The sector has enormous potential to thrive and grow in its own right in the UK and internationally; to provide alternative protein sources for pig, poultry and farmed fish producers and as a bioconversion agent, whereby black soldier fly larvae feed on and convert waste into feed, as well as producing other valuable by-products such as fertilisers, soil conditioners and lubricants.

His company is headquartered at the UK Agri-Tech Centre’s Northern Hub, where it conducts its breeding programme, raises larvae, runs its laboratory and R&D function, with production facilities close by. “This is where the genetics happens,” he continues.

“The other benefits come from being here on the campus and part of the UK Agri-Tech Centre, with whom we’ve run projects in the past. The exposure that we get here and the stakeholders we meet, such as the CEO of UKRI. Just by being here we’re able to engage with senior leaders of these kinds of organisations, which helps raise our profile.

“We’ve also had helpful exposure through the international delegations which have come here and, if we need to look outwards, we can do that too.”

As a member of INBIA (the UK Insect Bioconversion Association) Beta Bugs is now part of the IBC-Net project, which the UK Agri-Tech Centre is running, helping the sector to create a regulatory framework which is conducive to insect bioconversion sector growth in the UK.

“We would have been challenged to grow our business from a headcount of 5-20 if the facilities here had not existed,” Thomas concludes, “We’ve had access to equipment for R&D at low cost, rather than having to invest lots of capital to explore new avenues. It’s been a great way of doing early-stage R&D and seeing if it works or not. We’ve recently raised £2.1 million and, in total, around £5 million since we came here.

“The UK Agri-Tech Centre and the wider Easter Bush campus is the best place to build this business.”

Congratulations to Crover, who have recently started taking orders for their grain-sampling robots. Crover’s products aim to help prevent spoilage in stored grain by monitoring temperature, moisture, CO2 and depth, creating visual data to help farmers and growers make decisions on stored grain management.

Crover have just completed a project with the UK Agri-Tech Centre targeted at improving the resilience of cereal grains and oilseeds in storage and transportation, but their association with the UK Agri-Tech Centre can be traced back to their earliest days and on-farm test and trial of their prototype “grain-swimming robot”.

“We’ve come a long way since then,” says founder and CEO Dr. Lorenzo Conti, whose company has grown from two to 23 staff based mainly in Edinburgh, with some working remotely and even internationally. “Early on, access to the farm network was very helpful as we needed to test our prototypes.” Crover has now developed a range of robots: a small one for research, a larger one for basic-level sensing and a third one for sensing and sampling.

“It has been a process, but getting feedback has been really useful,” continues Lorenzo, “Farmers are very busy but the UK Agri-Tech Centre farmer network have been great lending us their time and facilities. Running a start-up has its ups and downs but we are in a better position than we have ever been. When we first started working with the UK Agri-Tech Centre and its legacy centre we were two or three people, now we have a staff of 23, mostly in Edinburgh, some working remotely and some in the USA. We’ve raised around £1.2m in the UK and USA and our target now is to gain revenue and scale up.

“We’ve learned so much from working with the UK Agri-Tech Centre that has helped us grow as a business – championing and connecting farmer problems with agri-tech solutions – that has made us more resilient as an organisation. We’ve been able to incorporate these lessons and to go out into the world and sell ourselves. In the first stages of being a start-up you have gaps in your knowledge and resources and the unknown unknowns are the hardest thing to overcome, but the UK Agri-Tech Centre has some really great people who have helped us through this.”

Agri-tech products and solutions often arrive from technology areas outwith agriculture, aquaculture and forestry, for example the automotive or satellite industries. With Oxi-Tech the plan was always to bring its technology to multiple sectors, including farming.

The UK Agri-Tech Centre has helped the company by providing a robust test and trial site, project expertise and industry connections. Oxi-Tech is growing, expanding its international reach and raising funds. Oxi-Tech’s product uses “Pulse Oxidation” to charge oxygen within water via small amounts of electricity, which can be used to clean and disinfect equipment, including robotic milking systems using cold water.

The benefits to dairy farmers are multiple: removing the need for chemicals, lowering energy costs and carbon footprint. Oxi-Tech’s product has also been demonstrated – via a project with the UK Agri-Tech Centre – to outperform traditional chemical-based cleaning methods.

The technology is also being used in healthcare settings and breweries, which have similar foundation systems to milking parlours. “We’re not in dairy; we’re science professionals but we need experts in each sector and Rob (Morrison), Hayley (Gerry) and the team were the experts,” says Paul Morris, Oxi-Tech’s CEO.

Oxi-Tech completed an Innovate UK-funded project at the UK Agri-Tech Centre’s South West Dairy Development Centre, an advanced, real-life working dairy farm, looking at removing chemicals from automated milking systems.

“Hayley and Rob were there at every stage, pulling together different strands of expertise. It was the first major project we had done on robotics on a fully working farm on a scale. It threw up an amazing opportunity to demonstrate that we can outperform conventional cleaning. It also showed how much energy was saved as we knocked out hot water usage. The UK Agri-Tech Centre was instrumental in writing up the report and showing the longer-term positive carbon impact.

Oxi-Tech have now doubled their staff headcount from three to six, taking on specialist dairy staff as they start to supply dairy units in the UK and internationally. “Since we finished the project we’ve done installations around the UK, plus our first Italian farm. We did our first Dutch project in January and our first project is due to start in Wisconsin.

“We’re closing a successful funding round just now – we’ve successfully raised £750,000 and we’re looking to close a multimillion-pound investment in the new few months,” says Paul. “The UK Agri-Tech Centre have been invaluable,” he concludes.

Mortality rates in newly planted trees are high: Rhizocore produces locally-adapted mycorrhizal fungi pellets which enhance tree planting success, speeding up establishment and accelerating early tree-growth rates.

Rhizocore have been at the UK Agri-Tech Centre Northern Hub for two years, where they have a full production facility. “It’s why we came here,” says Toby Parkes, CEO and founder of Rhizocore Technologies Ltd.

“We were a small science start-up needing scope to develop, but most facilities are fixed – the hub here offered us marvellous flexibility and we have been able to adapt the space as we’ve scaled. There is a lack of understanding for what scaling companies need. We need plumbing, electrics and temperature control; in the past year we have adjusted and moved our set-up three or four times. We can also conduct our quality control checks and ship from here.

“There is a huge appetite among start-ups like ours for space and we were very lucky to find a space here. Our company was created out of Edinburgh and we would have had to leave if we could not use these facilities. But since we’ve arrived, our headcount has grown from 8 to 25, split over two campuses with 10 in the hub. We’ve also started an operation in Australia.”

What if a new technology didn’t just solve a problem e.g. labour shortages, offer a return on investment, but created an entirely new income stream? Step up Upcycled Plant Protein, or UPP for short.

Broccoli harvesting is traditionally labour-intensive, and labour shortages are a well- documented problem. But, in addition to tackling the perennial problem of shortages in the workforce, UPP have found an opportunity to tackle another problem: waste. It might shock you to learn that about seventy per cent of a broccoli plant is discarded as only the floret makes it to the supermarket shelf.

UPP realised they could valorise the remainder of the plant, transforming it broccoli powder, fibre and juice – ingredients which could have multiple applications in the food industry, including burgers, sausages, soups, smoothies, pet food, sauces and bread. The protein source is comparable to pea and soy in terms of core amino acids; it could alleviate pressure on soy supply chains, with the added advantage that broccoli is hypoallergenic.

“The future is bright (green), the future is broccoli!” says Mark Green, CEO of UPP, which is at TRL 7-9. “UPP has raised £600,000 in equity, over £1,000,000 of loan finance and over £880,000 of (direct) grants (>£1.2m of total grants) and works closely with Harper Adams, the James Hutton Institute and the National Alternative Protein Centre (‘NAPIC’).” UPP employs ten people (9.4FTE) and expects to add another employee shortly.

“More importantly, UPP is at Heads-of terms with two major farming groups (UK and US) and has products in trial with 14 large food companies,” adds Mark.

UPP recently concluded the UKRI-funded SusProt: Sustainable Plant Protein from Vegetable Crop Sidestreams Project, which delivered pilot-scale production of protein from the roughly seventy per cent of the plant not being used, along with otherwise unharvested biomass.

The project involved the James Hutton Institute and the UK Agri-Tech Centre, leveraging the latter’s relationships within the UK ecosystem and allowing them to reduce the capital intensity of developing a complex stack of technologies.

UPP is based out of the UK Agri-Tech Centre’s Midlands Agri-Tech Innovation Hub, which has cutting-edge facilities and networking opportunities designed to help start-ups turn their business ideas into reality.